Wellhead Control Panels - WHCPs

High-quality, high-performing control and safety solutions

Operate your valves safely and reliably

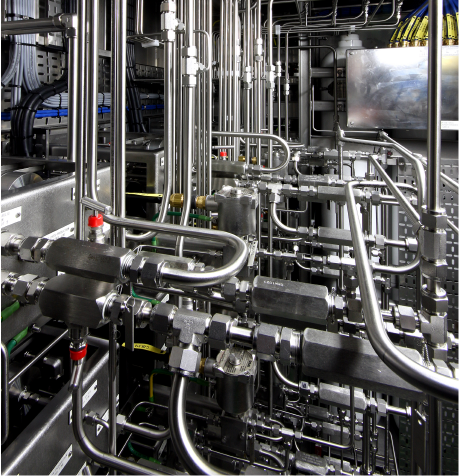

Performing a safety critical function on manned and unmanned platforms, our Wellhead Control Panels (WHCPs) are designed for monitoring, controlling and shutdown of various subsurface and surface valves.

This includes Subsurface Controlled Safety Valves (SCSSV), Surface Safety Valves (SSV), Master Valves (MV), Wing Valves (WV) and other wellhead safety valves (e.g. Choke, ESD, HIPPS) to ensure safe operation. All systems are designed and tailored to suit the individual project specifications or client developed, standardised design philosophies, always incorporating safety, environmental and statutory requirements.

Key features of the design include:

- High working pressures up to 1379barg / 20000psig

- Bladder and/or piston accumulators, (PED, ASME VIII Non or “U” stamped, AS 1210)

- Integral PLC interfaced to platform MCS or autonomous

- Integral autonomous MCC or interfaced to platform MCC

- Conventional A.C. 3 phase or 24v D.C. motor / pump assemblies and associated equipment fed from integral Solar Power system with autonomy in the event of ‘no sun-days’

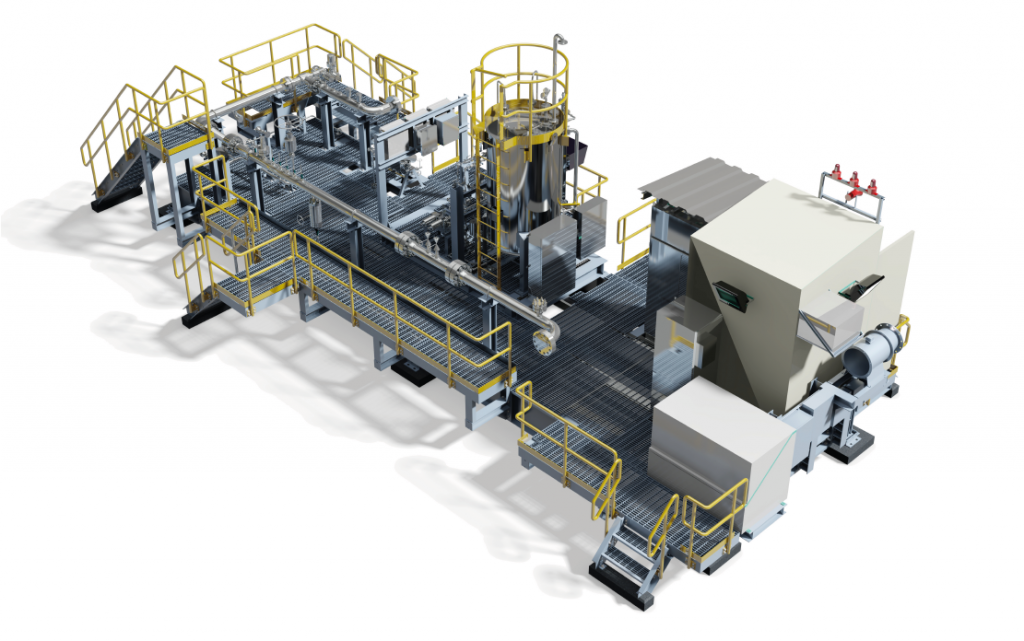

Our WHCPs are available as a standalone unit, or integrated as part of a Modular Wellsite Skid

A complete wellsite control and safety process system, all integrated onto a single skid. Including:

- Wellhead Control Panel with integrated PLC

- High-integrity Pressure Protection system to protect downstream instruments, and a corrosion inhibitor chemical injection package

- Flow meter, fully integrated controls and remote terminal unit for offsite control

Recent Projects

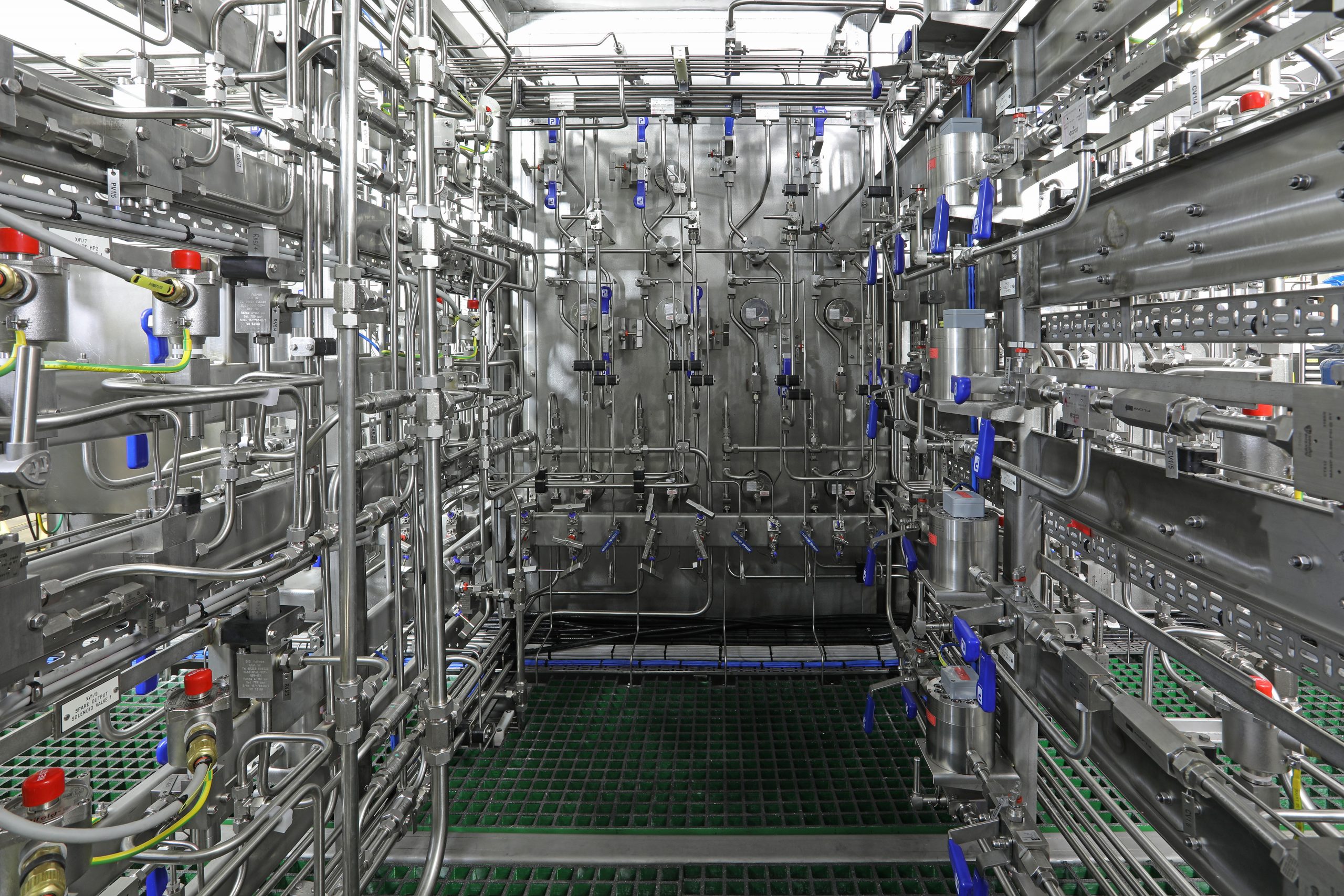

Image: Wellhead Control Panels, Middle East

Middle East

Locally designed and delivered WHCPs to perform a safety critical function for an oil and gas major: forming part of a safety instrumented function (SIF) loop for the valve arrangement or high-integrity pressure protection system (HIPPS).

- SIL 3 capable transmitters and emergency shutdown valves (1 out of 2 voting: 1oo2)

- Pressures ranging from 10 barg to 345 barg

- Complete with a fusible loop circuit, hydraulic emergency shutdown and process shutdown, and local / remote manual override functions.