Electrical Control Systems

In-house built electrical systems

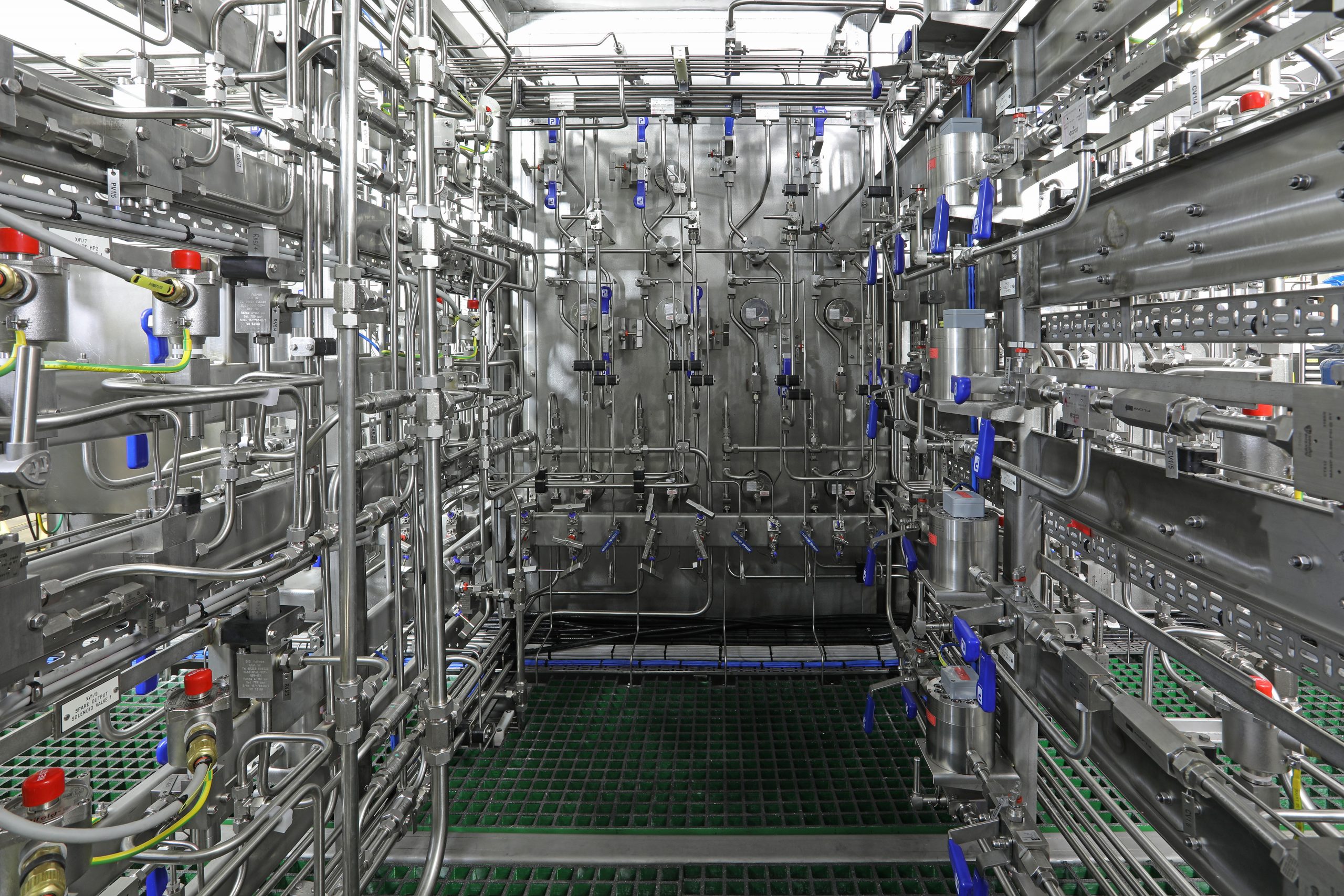

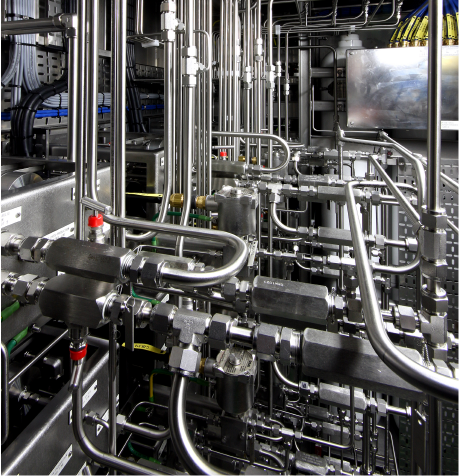

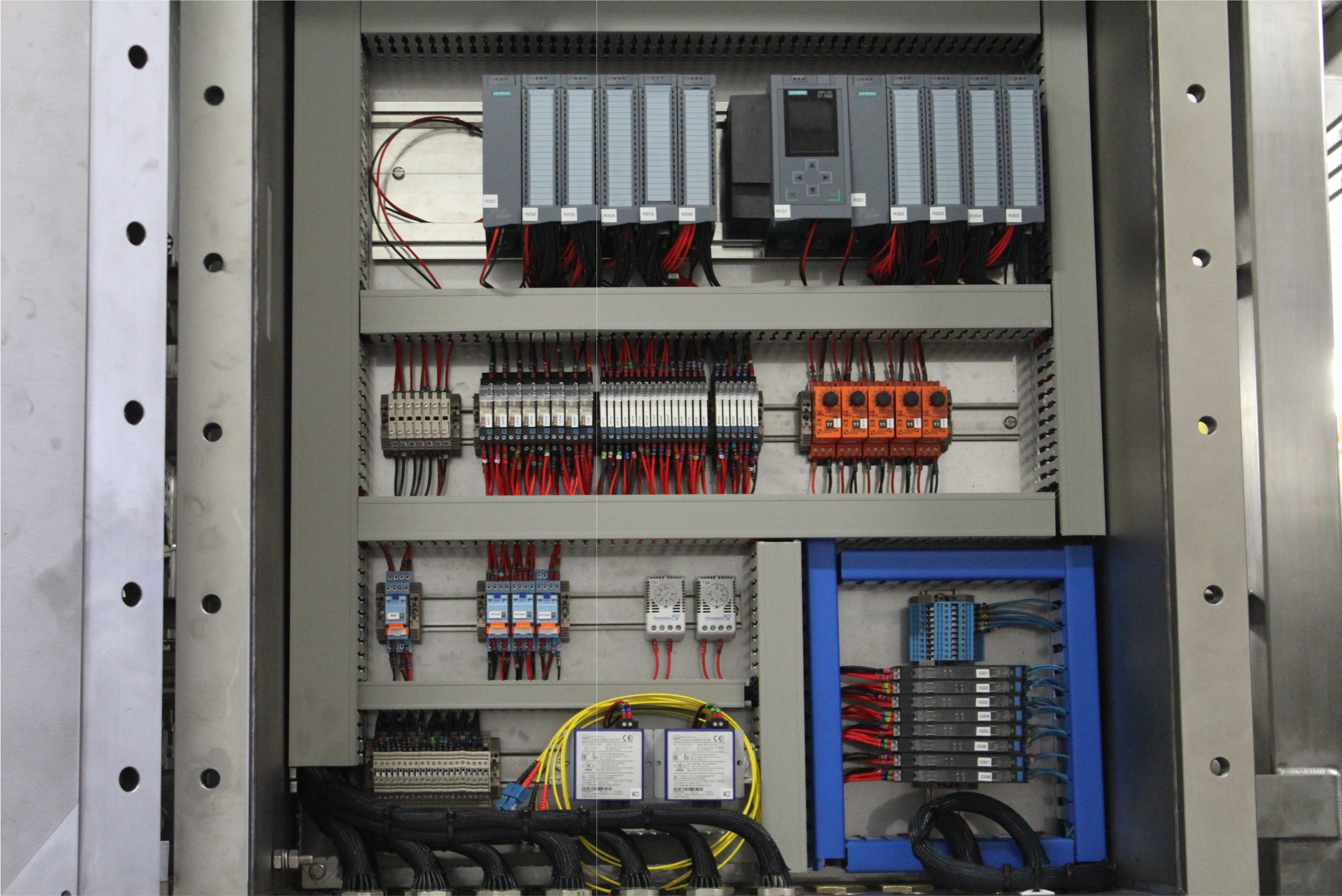

SMS design and manufacture an extensive range of Instrumentation, Control, and Automation panels for a wide range of industries – with all systems developed and built in-house.

All SMS systems can also be developed for multiple process areas and environments, from industrial to Zone 0 (NEC CI D1) hazardous areas (including certification to ATEX, IECEx, UKEX, NEC500 or 505).

Our hazardous area offering includes the largest 316L Ex d enclosures on the market, up to 944x1594x509 mm (465 litres), and custom, made-to-measure, Ex e & LCP panels.

Approved build partner of Bartec UK and Bartec Technor

SMS are proud to operate as an approved Hazardous Area Enclosure build partner of Bartec UK and Bartec Technor.

Operating on a mutual policy of technical excellence, SMS can design and assemble bespoke Ex d e units under Bartec’s expert certification.

Specialising in Bartec Technor’s large Stainless-Steel Ex d enclosures (764x964x325 mm up to 940x1590x455 mm) complete with Ex e terminal chambers, SMS offer exceptional flexibility for all your onshore and offshore control system requirements.

SMS can provide upgrades for various PLC systems from various manufacturers; for example Allen-Bradley PLC5 and Siemens S5 PLCs, to newer systems such as S7-1500s – and can fully advise on the performance enhancing solution best suited to your needs, including:

- Innovative solutions to enhance efficiency and performance

- System re-rates and modificaions to best suit the latest process conditions

- Modifications to retro-fit the latest technologies, such as IoT and remote monitoring

Key control system examples include:

- Master Control Systems (MCS)

- LV Switchboards / MCCs / Distribution panels

- Fire and Gas Panels

- Local Control Panels (LCPs)

- Junction Boxes

- ESD/Shutdown Panels

- Consoles and Control Desks

- Generator Control Systems

- Navigational Aids

Asset inspection and management

Failure to properly inspect and maintain your hazardous area equipment leaves you exposed to the risk of explosion/combustion. Giving you complete peace of mind, our team of inspection experts can manage your hazardous area inspection process for you, aligned to IEC requirements, including National Annexes as/where required.

With CompEx certified Technicians supported by our digital inspection tool, Inspection Manager, SMS can provide fast, secure and auditable inspection records to prove compliance, and prompt support in the event of any remedial actions.

Services include:

- HV, LV and instrumentation cable installations

- Cable management installations

- Electrical design, installation and commissioning in hazardous areas

- Ex audits or/and Ex registers to conform with European ATEX directive ATEX 2014/34/EU & 99/92/EC for 95/137, IECEx and UK Statutory Instrument 2016 No. 1107

- Electrical surveys

- Preparation and upkeep of client Ex equipment register

- Installation and maintenance of all Ex rated electrical equipment

- Visual, close and detailed inspection of Ex (Hazardous area) equipment using CompEx certified technicians

- Constructing installation and maintenance procedures

- Fire and gas installations

Ensuring a fast start-up

As an important part of project delivery, our engineers will ensure that your system is installed correctly and ready for use with maximum efficiency. Working collaboratively with your project manager and engineers, SMS technicians have the experience to provide you with all the advice you will require while your new system or system upgrade is being installed.

SMS technicians provide a full range of services from installation to pre-commissioning and commissioning, site acceptance testing and personnel introductory training.

We will also advise on operating and maintenance documentation, spares and fault finding.