Small Bore Tubing

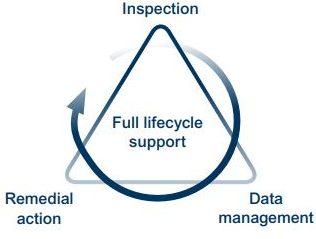

Complete SBT Integrity Management

- Optimised uptime

- Improved efficiency

- Enhanced safety

Ensure ongoing asset integrity

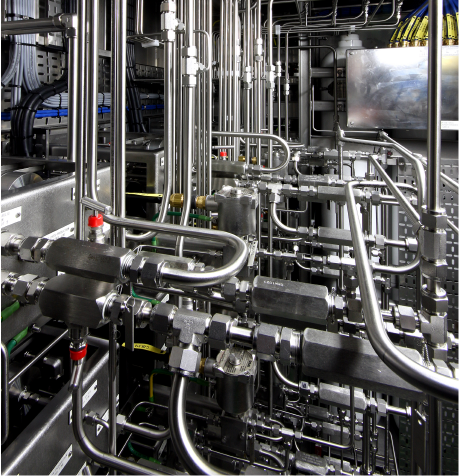

The failure of small-bore tubing (SBT) assemblies is one of the largest contributors to unplanned hydrocarbon releases in the oil and gas industry.

It is therefore essential that asset operators regularly inspect and are aware of the condition of the their SBT assemblies.

Why inspect?

Degradation of SBT assemblies, including corrosion occurs over time, resulting in reduced wall thickness. Instrumentation can become damaged in service.

Assemblies are also vulnerable without an effective inspection programme.

Leaks and failures can cause:

- Health and safety issues

- Environmental contamination

- Equipment damage

- Lost time production

Powered by SMS Inspection Manager

Our proprietary scheduling software ensures your inspections are conducted at the right time to optimise performance.

SMS’ Inspection services also helps you to prevent tubing and instrument failure through:

- Corrosion checks inside and around tube clamps and supports

- Visual inspection of all the associated equipment within the system

- Digital component tagging, documentation and photographs

- Auditable inspection and maintenance records

- Rapid reporting of failure modes with recommendations on corrective actions – all of which can be conducted by the SMS Service team for a prompt resolution

Our services

Our hydraulic experts can help ensure you meet health and safety requirements, exceed and prove compliance to legislation, and reduce the asset downtime associated with SBT assemblies through:

- Small Bore Tubing (SBT) Installation

- Small Bore Tubing (SBT) Inspection

- Small Bore Tubing (SBT) Maintenance

Our local teams – based in the United Kingdom, UAE, Saudi Arabia, Qatar, Singapore and India – work closely with our customers to understand their needs and deliver the right solution, with the flexibility, integrity and customer service you expect from a family business.

Being at the forefront of integrated solutions for over 60 years, our experts have an exceptional understanding of a wide range of hydraulic assets – whether supplied by SMS or another manufacturer.

With regular assessment of your equipment at predefined intervals, SMS’ engineers will promptly carry out all required proactive and/or reactive maintenance work to maximise your uptime.

Recent Project:

Small Bore Tubing Inspections

Development of a risk-based inspection strategy for SBT assemblies to prevent or mitigate HSE consequences that may result from a process safety or environmental release of hydrocarbon or high-pressure medium.

Meaning that SBT assemblies could be consistently assessed, tagged and categorised to advise of their current status, as well as inform future inspection and management planning.

The solution allowed our client to:

- “Register” individual assemblies to record their makeup and location

- “Manage” their assemblies through inspection and tagging

- “Report” on the status of their assemblies in a prompt and consistent manner

Ensure continued tubing and instrument performance:

Contact the SMS Inspection team today