Introducing Phil Adams, a new addition to the SMS' Hose and Components team

26 January 2022

1. Phil, welcome to SMS! Please introduce yourself.

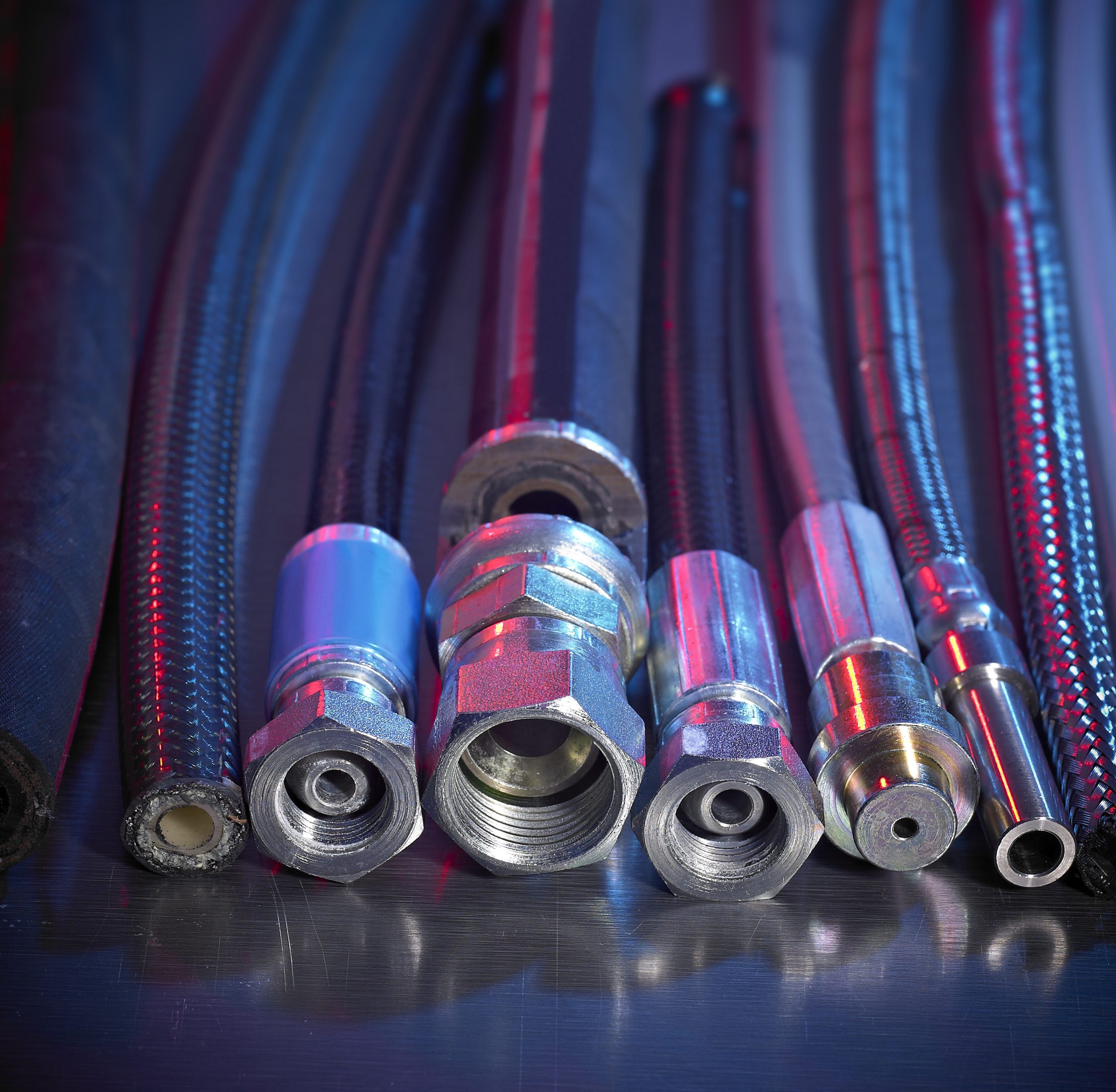

I’m Phil Adams, my 30-year career has been focused on hydraulic and industrial hoses, fittings, valves, pipe, flanges and other industrial products. Starting my career in the workshop assembling and testing hoses, through to surveying and fitting hoses both onshore and offshore.

In the last 15 years I’ve focused on sales and have supplied products to a diverse range of industries such as oil and gas, agriculture, machinery, construction, transport, and food.

2. What made you choose SMS as the next step in your career?

SMS is well known as a leader in the field of progressive engineering. Joining SMS felt like an exciting opportunity for my career. I wanted new challenges and the chance to be part of a successful global company.

I’ve known SMS for a long time. I bought and sold to SMS for the past 15 years and had previously worked with Chris Lee, Senior Sales Manager at SMS in the early part of my career.

Chris and I both started in the workshop assembling, testing, and fitting which helps us to understand clients’ needs as we know the complete process from start to finish.

Combined, Chris and I have a total of 55 years’ experience within the industry, which offers our team a wealth of knowledge on suppliers and products but also enables us to provide technical knowledge, a fast response to enquiries and competitive pricing. As a result, we can ensure clients receive the highest possible level of service.

I’m looking forward to working with the team and pushing our success to the next level.

3. The criticality of hoses within the industry – why is managing them so important?

A hydraulic hose lifespan depends on many factors such as environmental conditions, exposure to uncontrolled pressure, abrasion, cuts, or not following the instructions for fabrication. For this reason, hoses should be periodically inspected as neglected and unchecked flexible hoses can lead to production and equipment loss, which results in expensive down time or potential human injury.

SMS’ ‘Inspection Manager’ is an industry-leading answer to all these issues. It is a fully digital application used to support inspection tasks and was crucially developed in-house at SMS. This software enables companies to ensure the ongoing integrity, safety, and performance of their hose assemblies assessing fully clients’ hydraulic, pneumatic, and electrical systems while delivering instant, actionable insights. For me, ‘Inspection Manager’ demonstrates SMS’s commitment to deliver innovative best-in-class solutions to clients.

4. What are the environmental possibilities with hoses?

The most obvious risk to the environment is through hydraulic spills, which are caused by hose failure. However, through regular hose inspections, companies can reduce the risk by replacing the hoses before they fail.

Another way to reduce hose failure is to ensure you use quality products and trained technicians. SMS uses the best components, and we have in-house BFPA (British Fluid Power Association) trained technicians to inspect, assemble, test and fit hoses. Having the best expertise and components is so important in hosing.

5. What is your view on the future of hoses?

The industry is everchanging because hose manufacturers are constantly looking at ways to improve their hose products. For example, increased flexibility for easier installation, non-skive for quick assembly and reduced weight for more cost-effective transportation. These improvements are beneficial to us as suppliers and to our clients.

Hydraulic hoses are engrained in multiple industries such as machinery, construction, agricultural, manufacturing, mining, water supply and offshore. As hoses are easy to fit, flexible and cost effective, they will be around for many decades to come.

6. Do you have any tips to prepare for managing hoses during the wintertime?

A hose can fail anytime of the year, regardless of temperature, so my top tip is to ensure that all your hoses are regularly inspected by a professional because preventative maintenance is the best solution.

7. If you are not selling hoses, what do you like to do in your spare time?

I enjoy exercising and have recently bought a running machine, so if it’s raining, windy or cold outside, I have no excuse, not to run. I also enjoy relaxing at the weekend spending time with my family, having a takeaway, watching a film, or just going out for a walk.