Modifications and Upgrades

Modifications and upgrades, including IoT and digital to enhance your efficiency and performance

Innovative engineering solutions to enhance system performance, improve efficiency and reduce operating costs while ensuring ongoing compliance and asset integrity.

- Hydraulic and electrical control system upgrades

- System repair, modification and replacement

- IoT, remote monitoring and control updates

- Re-rates to suit the latest process conditions

Proactive management of ageing equipment means that assets can be repaired, refurbished, replaced or upgraded prior to the point of failure – supporting operational continuity and negating the high costs associated with reactive measures.

Through health and criticality assessment of your equipment, our experts help to proactively manage your risks of unplanned downtime caused by asset failure and obsolescence. This can include the storage of replacement parts to extend the product’s life beyond point of obsolescence.

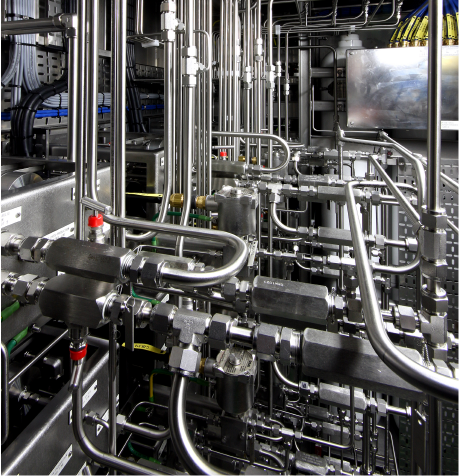

Electrical upgrades

Electrical and instrumentation

Upgrading the PLC within your existing Ex Control Panel may be due to obsolescence or a requirement to add additional features. SMS can fully advise on the performance enhancing solution best suited to your needs providing re-certification to ATEX as required, including:

- Innovative solutions to enhance efficiency and performance

- System re-rates and modifications to best suit the latest process conditions

- Modifications to retro-fit the latest technologies, such as IoT and remote monitoring

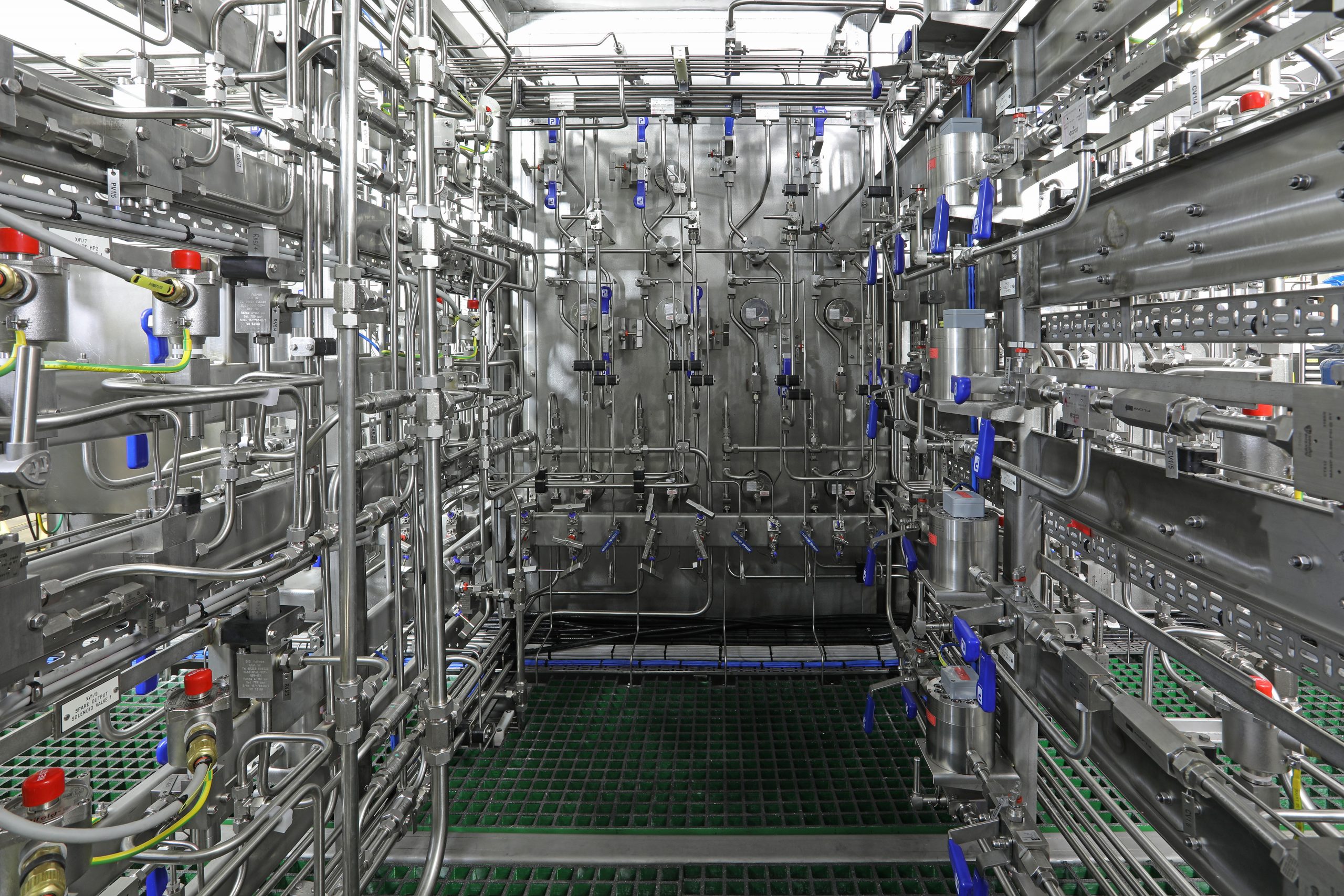

Hydraulic upgrades

Hydraulic systems

Increasing reliability and productivity whilst reducing incidents of outages and equipment failures on safety critical systems such as hydraulic controls and high-pressure components. All SMS hydraulic solutions can be upgraded, including:

- Hydraulic Power Units (HPUs)

- Wellhead Control Panels (WHCPs)

- Topside Umbilical Termination Units (TUTUs)

"The management team wish to recognise SMS for your admirable commitment and drive to see a successful conclusion to the SSIV (Subsea Isolation Valve) proof of concept study. Furthermore, the passion and enthusiasm within your staff has also been recognised as a key factor for the results and achievements made in recent months with regard the tactical repairs made to the legacy SSIV equipment."

UK Team Lead, North Sea Supermajor

Obsolescence management

Equipment obsolescence can have a severe impact on the availability of your instrumentation and systems, especially if your incumbent system fails.

Regardless of OEM, our experts can provide a high standard of timely support to meet your obsolescence management requirements.

-

Assessing your equipment

Adhering to the best practice guidelines set out by the International Standard for Obsolescence Management (IEC 62402), our service specialists will assess your equipment’s impact criticality and its probability of obsolescence to inform required actions. Furthermore, we can offer mitigation and resolution strategies for different scenarios.

-

Conducting equipment analyses

In cases where the equipment is or will soon become obsolete, we can assist by conducting equipment purchase analyses, investigating other off-the-shelf sources and even storing discontinued equipment with our Parts and Spares Management Services.

-

Advising on alternative solutions

Alternatively, with our leading systems integration knowledge and experience, our technical experts can advise suitable substitute equipment, engineer alternative solutions including system redesigns to accommodate any superseding parts, or provide comprehensive upgrade options.